MULTICOLOUR LED DISPLAY

Minor Project Report

Submitted in

partial fulfillment of the requirements

For the award of the degree of

Bachelor of Technology

In

Electronics and Communication Engineering

Of

COCHIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Submitted by

Aleena Emmanuel(02)

Arun Prabhakar(08)

Arvind G Shankar(10)

Raji James(30)

Department of

Electronics & Communication Engineering

Model Engineering

College

Kochi 682 021

GOVERNMENT MODEL ENGINEERING COLLEGE

THRIKKAKKARA

KOCHI

DEPARTMENT

OF ELECTRONICS AND COMMUNICATION

ENGINEERING

Cochin

University of Science and Technology

BONAFIDE CERTIFICATE

This is to certify that the mini project report

entitled

..

Submitted by

..

..

..

..

..

is a

bonafide account of the work done by him/her under our supervision.

|

Mrs.

Minimol M.G

Head of the Department

|

Mrs Anjana Devi

Project Guide

|

Mr Vinu Thomas

Project Coordinator

|

ACKNOWLEDGEMENT

At this moment of accomplishment, we are

presenting our work with great pride and pleasure, we would like to express our

sincere gratitude to all those who helped us in the successful completion of

our venture. First of all, we would like to thank our Principal Prof. Suresh Kumar P who provided us

with all facilities and amenities for the development of our project. We would

like to thank our HOD, Dr Mini M G for

helping us in the successful accomplishment of our project. We are exceedingly

grateful to our project coordinator Assistant Professor, Mr. Vinu Thomas for his

timely and valuable suggestions. We would also like to thank our project

guide Senior Lecturer Mrs.Anjana Devi who gave us constant

guidance and support throughout this journey of turbulence.

We also sincerely

thank Mr. Biju Mathew, Mrs. Geetha,

Lab Technicians, department of Electronics and Communication for their constant

support and encouragement for our project.

We would also

like to thank our parents and friends for their over whelming and whole hearted

encouragement and support without which this would not have been successful.

Above all we

thank God almighty for constantly motivating us with His love, and giving us

courage at each stride to step forward with confidence and self belief.

ABSTRACT

LED's are a fantastic way to illuminate any kind of sign,

be it lettering or panels. LED Dot-Matrix Displays are a common sight

nowadays on streets, malls, buildings, parks and other public places. It is a

way of visual information where large LCD and other display become too much

expensive. The commonly seen displays are single coloured or having 2 or 3

colours .But here multicoloured LED display is being introduced .This project

provides an efficient and scalable approach to LED Dot Matrix displays.

The system is comprised of a tricolor dot matrix display panel

with an interface circuit to a computer. It also comprises an executive program

that runs on the computer for the display control of characters, decorative

pattern or messages on the display panel. A multicolour LED Indoor Advertising Display can be used by companies to advertise even in bright

day-light conditions. The display board displays any character

entered from the host computer which is interfaced using USB to a

microcontroller that initializes the led driver. The advantage of this project

is that size of the display board can be increased row wise and column wise

without making any changes in the circuitry since display board is the

repetition of a small independent module.

Contents

Chapter 1 Project

Overview.. 7

1.1

Introduction. 7

1.2

Objective. 8

1.3

Specifications. 8

Chapter 2 System Overview.. 9

2.1

Block Diagram.. 9

2.1.1 LED Matrix. 9

2.1.2 LED Driver. 10

2.1.3 Microcontroller. 10

2.1.4 Universal Serial Bus Interface. 10

2.2

Advantages and applications. 10

Chapter 3 Project Design. 12

3.1

LED Module. 12

3.1.1 LED Array. 12

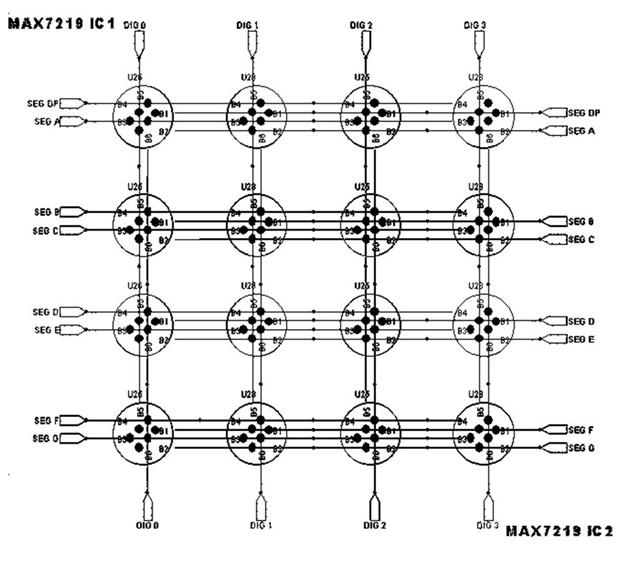

3.1.2 LED Driver MAX7219. 13

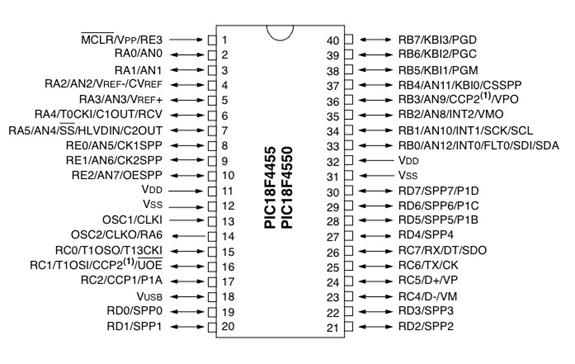

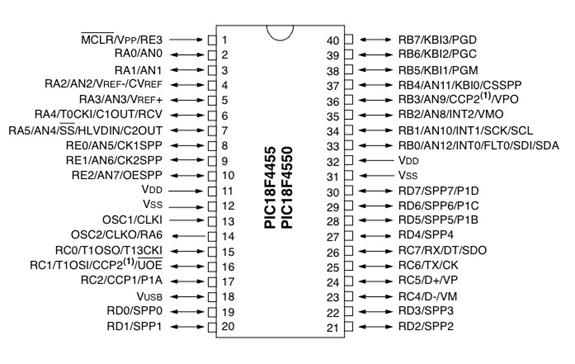

3.2.1 PIC18F4550. 17

3.2.2 20MHz Crystal oscillator. 19

3.2.3 USB 2.0. 19

3.2.4 USB Connector. 20

3.2.5 Push buttons "Reset" and

"Program". 20

3.2.6 Status

LEDs. 20

3.3

Power Supply. 22

3.3.1 Transformer. 23

3.3.2 Bridge rectifier. 23

3.3.3 Regulator IC 7805. 23

3.3.4 Power Transistor 2n2955. 24

3.4

Circuit 24

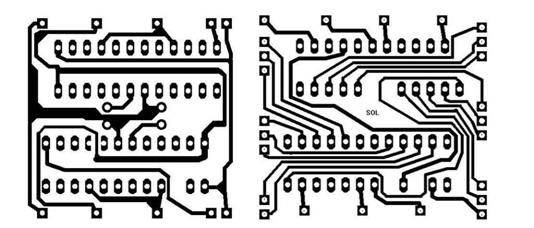

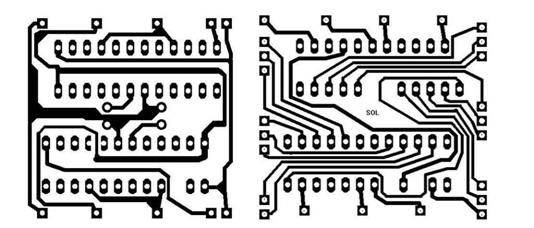

Chapter 4 PCB Design. 25

4.1

LED Array. 25

4.2

LED DRIVER CIRCUIT. 26

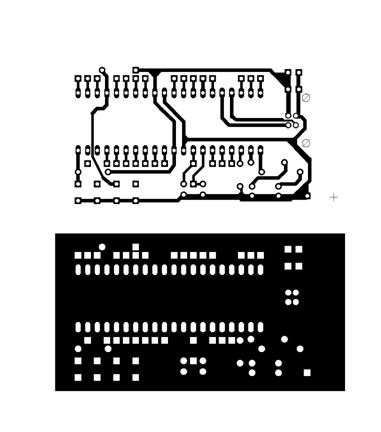

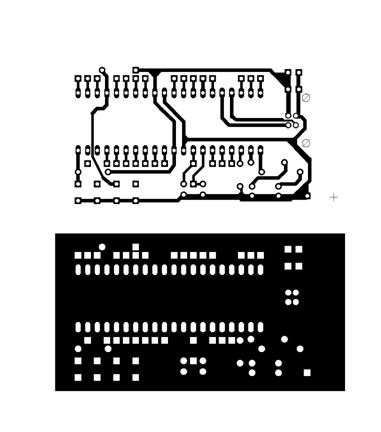

4.3 USB INTERFACE. 27

Chapter 5 Software. 28

5.1

Flow Charts. 28

5.1.1 Software Flow.. 28

5.1.2 Firmware Flow.. 28

5.2

Source Codes. 29

5.2.1 Software Code. 29

5.2.2 Firmware Code. 32

Chapter 6 Conclusion. 36

6.1

Observations. 36

6.2

Future Scope. 36

Bibliography. 37

Appendix. 38

APPENDIX

A Cost Report 38

APPENDIX

B Datasheets. 38

List of Figures

Figure 1 Block Diagram.. 9

Figure 2 RGB LED Pinout. 12

Figure 3 MAX7219 Pinout. 13

Figure 4 RSET vs. Segment Current and LED Forward Voltage. 14

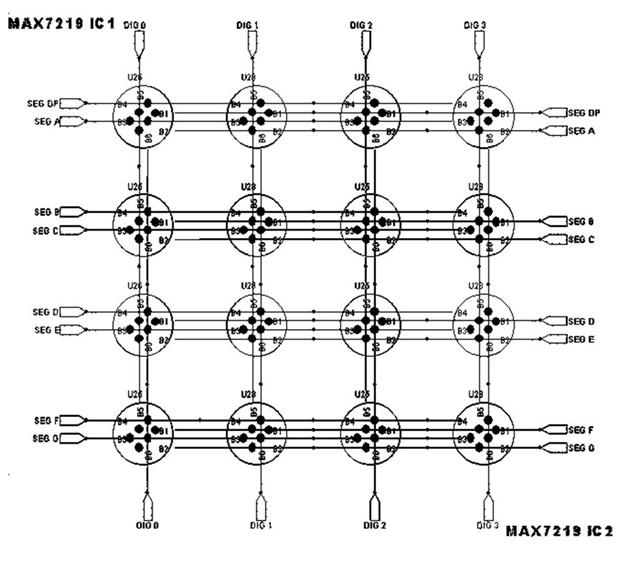

Figure 5 Led Driver Circuit. 15

Figure 6 Led Array. 16

Figure 7 PIC18F4550 Pin

out. 18

Figure 8 USB Pin

Description. 19

Figure 9 USB CONNECTOR. 20

Figure 10 State LED Status. 21

Figure 11 Schematic of the USB

interface. 21

Figure 12 SCHEMATIC OF LED DRIVER

WITH PIC. 22

Figure 13 Basic block diagram of

power supply. 22

Figure 14 7805 Pinout. 24

Figure 15 Power Supply

Circuit. 24

Figure 16 LED PCB. 26

Figure 17 MAX7219 PCB. 26

Figure 18 Microcontroller

PCB. 27

Figure 19 Cost Report. 38

Visual impact is the most effective mode of influencing

human minds which is the main aim of adverstisements etc. A display device

serves this purpose.A display device

is a device for presentation of information for visual or tactile reception, acquired, stored,

or transmitted in various forms. The display devices used to display information on machines, clocks, railway

departure indicators and many other devices require a simple display of limited

resolution. The display consists of a matrix of lights or mechanical indicators arranged in a

rectangular configuration (other shapes are also possible, although not common)

such that by switching on or off selected lights, text or graphics can be

displayed. Various modifications has been made in the display board.

Now LED display panels are widely used throughout the world in

all situations to create images for visual displays in a variety of applications

including communication and visual display devices. LED array display board is

a popular instrument for commercial usage. Many banks, shops and cinemas are

willing to install one piece of it because of its versatility. LED array

display board can be very bright and eye-catching. Display signs used for

advertising or for displaying direction or other information to motorists have

an important feature in common. They should be eye-catching and their

information should be easy to absorb. In advertising, a signboard made of an

LED display generally standing at a conspicuous location, such as a bustling

road, is widely used. The LED display comprises a plurality of LEDs controlled

by special hardware and software to perform moving images on a screen thereof

to attract the attention of passersby. The LED array display board is used in a

bank to show the current stock market value, currency exchange rate and

interests rate. It can also be used in a shop to tell people the prices and

other commercial information. LED display board serves the above purposes with

advantages rendered by LEDs

- LEDs produce more

light per watt than incandescent bulbs; this is useful in battery powered

or energy-saving devices.

- LEDs can emit light

of an intended color without the use of color filters that traditional

lighting methods require. This is more efficient and can lower initial

costs.

- The solid package of

the LED can be designed to focus its light. Incandescent and fluorescent

sources often require an external reflector to collect light and direct it

in a usable manner.

- LEDs are

ideal for use in applications that are subject to frequent on-off cycling,

unlike fluorescent lamps that burn out more quickly when cycled

frequently, or HID lamps that require a long time before restarting.

- LEDs,

being solid state components, are difficult to damage with external shock.

Fluorescent and incandescent bulbs are easily broken if dropped on the

ground.

- LEDs can

have a relatively long useful life.

- LEDs

light up very quickly

- LEDs can

be very small and are easily populated onto printed circuit boards.

Organic light emitting diodes (OLED) are a promising

technology for flat-panel displays. Owing to high brightness, fast response

speed, light weight, thin and small features, full color, no viewing angle

differences, no need for an LCD back-light board and low electrical consumption, an

organic light emitting diode display takes the lead to substitute a twist nomadic

(TN), a super twist nomadic (STN) liquid crystal display, or a small-sized

thin-film transistor (TFT) LCD

display. Light emitting diodes are

useful in a wide range of high and low resolution display devices.

Display technology pervades all aspects of present day life,

from televisions to automobile dashboards to laptop computers to digital

cameras. Single coloured LED display

boards are very common nowadays. The same yellow or red coloured board is not

attractive .The introduction of multicoloured LEDs into the display boards make

them attractive. This project is oriented towards the

development of a prototype of a multicoloured LED display board which is being

controlled by an LED driver. The use of multicolour LED opens door to many

applications. The display board is made on readily available components. The

important requirement is that the display board should have long life expectancy, high

tolerance to humidity, low power consumption and minimal heat generation. The

fundamental part is a 4X4 LED module which could be repeated column wise or row

wise to enlarge the display without any change in circuitry. Both single line

and double line display could be affected. Motivation towards the project was

to make available a readily expandable multicolour display board which can be

used for multiple purposes.

- 4 x 4 multicoloured LED modules (8)

- USB interface

- High speed response

- Power supply requirement :5V ,4A

A

simplified block diagram is given below.

A 4X4 LED module is the

fundamental part of the display. LED display panels use matrix addressing

techniques to organize the light emitting elements or pixels into a number of

rows and columns with each pixel at an intersection of a particular row and a

particular column. A light emitting device (LED) display is typically supplied

with data addressed from graphical memory location in accordance with a

column-major display. The LED display illuminates pixels on a column basis by

providing sourcing and sinking currents to diodes in the display. An LED

display is typically made up of various dots arranged in a matrix pattern

having rows and columns. The dots are usually called pixels where the pixels

are made up of several LEDs. Illuminating the pixel requires activating an

intersecting row and column thereby providing a closed current path that

includes the pixel to be illuminated.

The individual

LEDs emit light of three basic colours: red, green and blue. Typically, each

pixel is composed of at least one LED of each colour. In LED displays, one dot

is formed by utilizing a plurality of cannon ball-shaped LED lamps each having

different luminescent colours. The intensity of the LEDs is usually controlled

by controlling the current to the individual LEDs. This is done by means of a

led driver. A pixel can produce a specific perceived colour by varying the

drive to the three colours of LEDs that comprise the pixel. By controlling the

current drive to each of the LEDs that makes up a pixel and in turn controlling

each of the pixels that make up a matrix of pixels, an LED display device is

capable of displaying a plurality of colours and light intensities so as to

realize, for example, a multi-colour display. As the resolution of displays

increases, the number of pixels in each row and column also increases and the

amount of time available to illuminate each pixel decreases. As the

illumination time decreases, each pixel must be driven with a larger current to

provide a pixel intensity that maintains acceptable image intensity and viewing

characteristics.

Light Emitting Diode:

Multicolour LEDs are used to provide colourful display. They primarily

provide three colours: red, green, and blue. By the combination of these

colours in correct proportion many varieties of colour are possible. The three

colours could be individually controlled as controlling three single LEDs.

The control of the LED display module is done by means of

LED driver. It is programmable using microcontroller. An LED Driver has a shift register embedded that will take

data in serial format and transfer it to parallel. It performs following

functions:

o

It controls the intensity and brightness of the display

o

It controls the colour of the display

o

It decides which led is to be lighted to display specific

character

o

It receives the input signal specifying the character to be

displayed from the microcontroller which is controlled by host computer using

USB interface.

The character to be displayed is inputted from

the host computer using USB interface. PIC18F4550 is used to provide the USB

interface to the LED driver which controls the display. The PIC is programmed

such that it provides USB interface. A self programmable PIC is used.

It provides the communication between the host computer and

display board. It also can provide power supply for the microcontroller.

Advantages:

ฐ No

More Monotonous Same Advertisement again and again for days/months. (message to

be displayed can be changed instantaneously)

ฐ Instant,

Current and Hot Topics reach the Public immediately.

ฐ Common

Display system which displays instant messages like Flash News, in

Places like

exhibitions, Road side Hoardings.

ฐ Instant

Message Delivery.

ฐ Easy

to change messages.

ฐ Attractive

multicolour display.

ฐ A

high density display board could be used for video display.

ฐ Eye

catching display serving the purpose of advertisements.

ฐ Media

for indoor & outdoor advertising and are clearly visible from very long

distance.

Applications:

ฐ Advertisement

Hoardings with dynamic update of Flash News.

ฐ Instant

update of Petrol Prices to all petrol Bunks from a Central office.

ฐ Stock

Tickers, which displays dynamically current value of the Stocks and the

trend.

ฐ Current

Prices of Commodities at different parts of the country.

ฐ Shopping

malls & retail stores.

ฐ Railway

information.

ฐ Amusement

Parks & Zoo's.

ฐ Traffic

Information.

ฐ

Pedestrian countdown system for maximum

pedestrian safety.

Hardware requirements:

o

4 x 4

LED array

o

LED

driver MAX 7219

o

Resistors

22 KΩ, 15 KΩ

o

Capacitor

0.01μF

It consists of 16 multicoloured LEDs arranged in 4x4 matrix format. The

LED used is LED 339-1VRKGBBW-1 from ever bright. It is a multicoloured common

cathode led with 2 Blue LEDs, 1 Green and 1 Red LED. It

has 6 pins: 2 Blue Anodes & their common cathode, 1 Green and 1 Red anode

& their common cathode. Blue LEDs have lower brightness

compared to Red/Green, so there are 2 Blue LEDs in this package. Multicolour LED provides primarily blue,

green, yellow colour by giving bias to appropriate pins.

Specifications:

Specifications:

If (typical

forward current): 20mA

Cut in Voltage

Red: 1.6V

Green: 1.8V

Blue: 2.5V

Figure

2 RGB LED Pinout

Also by varying the current to various pins

a variety of colours can be obtained. The red, blue, green anode lines are

connected in horizontal lines while cathode lines in vertical lines. Since the

LEDs are arranged in matrix format each LED could be controlled individually.

LED driver used is MAX7219. It can drive 64

single LEDs. The 7219 can source up to 40mA and control an 8x8 single LED

matrix. (Here 2 MAX7219 is used to control a 4X4 matrix). Individual LEDs can

be turned on or off with 3 wire serial interface (CLK, DATA, LOAD). 16 Brightness

steps are also provided, which can control the brightness of all the 64 LEDs.

Thus it provides both software and hardware control of brightness. It drives

common cathode LED display. It provides 100MHz serial interface.

The LED

driver has a 16 bit shift register. Input signals are CLK, DIN, and LOAD.

Serial data at DIN, sent in 16-bit packets, is shifted into the internal 16-bit

shift register with each rising edge of CLK regardless of the state of LOAD.

The data is then latched into either the digit or control registers on the

rising edge of LOAD/CS. LOAD/CS must go high concurrently with or after the

16th rising clock edge, but before the next rising clock edge or data will be

lost. Data at DIN is propagated through the shift register and appears at DOUT

16. 5 clock cycles later. Data is clocked out on the falling edge of CLK.

Figure 3 MAX7219 Pinout

Specifications:

Operating Supply Voltage: 5V

Shutdown Supply Current: 150μA

Operating Supply Current: 330 mA

ISEG : -40mA

Resistor

(RSET)

The MAX7219 allows display brightness to be controlled with an

external resistor (RSET) connected between V+ and ISET. It is used to set the

peak segment current. The peak current sourced from the segment drivers is

nominally 100 times the current entering ISET. Its minimum value should be

9.53kΩ, which typically sets the segment current at 40mA. Display

brightness can also be controlled digitally by using the intensity register. Digital

control of display brightness is provided by an internal pulse-width modulator,

which is controlled by the lower nibble of the intensity register. The

modulator scales the average segment current in 16 steps from a maximum of

31/32 down to 1/32 of the peak current set by RSET .

Figure 4 RSET vs. Segment Current and LED Forward Voltage

Design

MAX7219 can drive 64 single LEDs. A multicolour led is equal to 3 single

LEDs. Thus two MAX7219 is used to drive a 4 x 4 LED module. Each MAX7219 has 8

segment lines (SEG Dp through SEG G) to control the anode (horizontal) lines of

the display and 8 digit lines (DIG0 through DIG7) to control the cathode

(vertical) lines. Here one MAX7219 is used to control the red and green LEDs

which have a common cathode. Another MAX7219 is used to control the two blue

LEDs. Only 4 digit lines of an LED driver are used.

The

current value is to be set at 20mA which is the safe value for the LED. This is

provided by selecting a resistance equal to 22K.

For the

expansion of the display, cascading of the MAX7219s is done. This is done by connecting LOAD and

CLK inputs of all the devices together and connecting DOUT to DIN on adjacent devices.

DOUT is a CMOS logic-level output that easily drives DIN of successively

cascaded parts.

LED Driver Circuit

Figure 5 Led Driver Circuit

SCHEMATIC OF 4 X 4 LED MODULE

Figure 6 Led Array

3.2 USB Interface

Hardware

Requirements:

o

PIC18F4550

o

20MHz Crystal

oscillator

o

USB 2.0

o

USB Connector

o

Push buttons "Reset" and

"Program"

o

Resistors

o

Capacitors

o

Status LEDs

The Microchipฎ PIC18F4550 microcontroller is the heart of the board. It is a programmable microcontroller with 32Kbytes of flash program memory and 2Kbytes of general purpose SRAM. It has 13 A/D inputs making the system ideal for use in real-world monitoring applications and 18 general purpose I/O ports. There are 2 PWM channels, one 8-bit Timer and three 16-bit Timers. Auxiliary communication is provided by RS232 Communication (1 Channel), USB Communication (1 Channel), SPI (3-wire SPI Module), IฒC (with Master/Slave Mode). This PIC is provided with boot loader which enables self programming (Self-Programmable under Software Control) of the PIC. It has the following Universal Serial Bus features:

USB V2.0 Compliant

Low Speed (1.5 Mb/s) and Full Speed (12 Mb/s)

Supports Control, Interrupt, Isochronous and Bulk Transfers

Supports up to 32 Endpoints (16 bidirectional)

1-Kbyte Dual Access RAM for USB

On-Chip USB Transceiver with On-Chip Voltage

It has a Flexible Oscillator

Structure with following features:

Four Crystal modes, including High Precision PLL for USB

Two External Clock modes, up to 48 MHz

Internal Oscillator Block:

- 8 user-selectable frequencies, from 31 kHz to 8 MHz

- User-tunable to compensate for frequency drift

Secondary Oscillator using Timer1 @ 32 kHz

Dual Oscillator options allow microcontroller and USB module to run at different clock

speeds

Fail-Safe Clock Monitor:

Allows for safe shutdown if

any clock stops

PIC18F4550 PINOUT

Figure 7 PIC18F4550 Pin out

It has

high-current sink/source of 25 mA/25 mA. There are three external interrupts.

Four Timer modules (Timer0 to Timer3) are present. It has a C Compiler

Optimized Architecture with Extended Instruction Set.

Specifications

Voltage on any pin with respect to VSS - -0.3V to (VDD + 0.3V)

Voltage on VDD with respect to VSS - -0.3V to +7.5V

Total power dissipation

- 1.0W

Maximum current out of VSS pin -

300 mA

Maximum current into VDD pin -

250 mA

Maximum output current sunk by any I/O pin -

25 mA

Maximum output current sourced by any I/O pin -

25 mA

Maximum current sunk by all ports - 200 mA

Maximum current sourced by all ports - 200

mA

The crystal oscillator is used to provide

the clock for the PIC. A crystal oscillator has a very stable Q. It is

equivalent to an LCR circuit. It oscillates at its resonating frequency. Here

the crystal provides 20 MHz clock to the PIC. It requires resistors and

capacitors to oscillate properly

Universal Serial Bus (USB) is a serial bus standard to interface . Its

features include providing power to low-consumption devices without the need

for an external power supply and allowing many devices to be used without

requiring manufacturer specific, individual device drivers to be installed. A USB cable has two wires for power (+5 volts and ground)

and a twisted pair of wires to carry the data.

USB supports

three data rates: A Low Speed (1.1, 2.0) rate of 1.5 Mbit/s (187.5 kB/s) that is mostly used for Human Interface Devices (HID)

such as keyboards, mice, and joysticks and a Full Speed (1.1, 2.0) rate of 12 Mbit/s (1.5 MB/s). Full Speed devices divide the USB bandwidth between

them in a first-come first-served basis and it is not uncommon to run out of

bandwidth with several isochronous devices. All USB Hubs

support Full Speed. A Hi-Speed

(2.0) rate of 480 Mbit/s (60 MB/s).

|

Pin

|

Name

|

Cable colour

|

Description

|

|

1

|

VCC

|

Red

|

+5V

|

|

2

|

D−

|

White

|

Data −

|

|

3

|

D+

|

Green

|

Data +

|

|

4

|

GND

|

Black

|

Ground

|

Figure 8 USB Pin Description

The USB standard uses "A" and "B" connectors to avoid confusion:

o

"A" connectors head "upstream" toward the computer.

o

"B" connectors head "downstream" and connect to

individual devices.

USB 2.0 has added higher maximum speed of 480 Mbit/s. The USB 2.0 specification

covers all three speeds 480 Mbps, 12 Mbps, and 1.5 Mbps. USB 2.0 (High-speed USB) provides additional

bandwidth for multimedia and storage applications and has a data transmission

speed 40 times faster than USB 1.1.

The USB Connector is a standard "type

B" connector. There are four connections in a USB cable, two of which

supply power while the other two are the communication lines D+ and D-. By

these pins information is transferred between the host computer and the

PIC when it is being programmed, and

while firmware sends or receives data with the computer if it is a HID

application.

Figure 9 USB CONNECTOR

The two

buttons are used during the process of programming the PIC. If the Reset button

is pushed while holding down the Program button, the PIC will enter the boot

loader mode, which will allow a new application to be loaded into the PIC. One

of the general purpose I/O pins is dedicated to the "program" button

to enter boot loading mode

The reset button is connecter to MCLR pin.

They show the

state of USB. The various conditions are shown below.

Figure 10 State LED Status

Design:

For providing the clock

using crystal oscillator 22pF capacitors and 1Mohm resistors are required. They

make the crystal oscillate properly. A capacitor 0.47μF is connected across the pin

18. It is required for the proper functioning of internal voltage regulator. A

decoupling capacitor of value 0.1μF is connected across the power pins of USB socket. Status

LEDs are connected at pins 19 and 20.

Figure 11 Schematic

of the USB interface

Figure 12 SCHEMATIC

OF LED DRIVER WITH PIC

The SPI interface

of the PIC 18f4550 is connected to the respective pins of the MAX 7219.

Figure 13 Basic block diagram of power

supply

Hardware

requirements:

o

A

Transformer (8-0-8V,1A)

o

Bridge

Rectifier (Power Diode BY127)

o

Regulator

IC 7805

o

Power

Transistor 2n2955

It steps down the input

230V, 50 Hz AC to 8-0-8 V, 1A.

The bridge rectifier provides full wave

rectification from a two wire AC input. It is formed of power diode

BY127. The ac input voltage is applied to the

diagonally opposite ends of the bridge. . The load resistance is connected

between the other two ends of the bridge. For the positive half cycle of the

input ac voltage, diodes D1 and D3 conduct, whereas diodes D2 and D4 remain in

the OFF state. The conducting diodes will be in series with the load resistance

RL and hence the load current flows through RL. For the

negative half cycle of the input ac voltage, diodes D2 and D4 conduct whereas,

D1 and D3 remain OFF. The conducting diodes D2 and D4 will be in series with

the load resistance RL and hence the current flows through RL

in the same direction as in the previous half cycle. Thus a bi-directional wave

is converted into a unidirectional wave.

The +5 volt power supply is based on the commercial 7805

voltage regulator IC. This IC contains all the circuitry needed to accept any

input voltage from 8 to 18 volts and produce a steady +5 volt output, accurate

to within 5% (0.25 volt). It also contains current-limiting circuitry and

thermal overload protection, so that the IC won't be damaged in case of

excessive load current; it will reduce its output voltage instead.

Specifications

|

Output Voltage

|

5V

|

|

Ripple rejection ratio

|

78dB

|

|

Input regulation

|

3mV

|

|

Load regulation

|

15mV

|

Figure 14 7805 Pinout

It is used to boost the output current.

Figure 15 Power Supply Circuit

The

bridge rectifier rectifies the ac input signal. This is being smoothened by the

capacitor C1, the output is regulated by IC 7805. A power transistor is

used to supply extra current to the load the regulator, maintaining a constant

voltage. Currents up to 650mA will flow through the regulator, above this

value and the power transistor will start to conduct, supplying the extra

current to the load. This should be on an adequate heat sink as it is likely to

get rather hot. For a 5v regulator 7805.

The input voltage should be a few volts higher to allow for voltage drops.

Assume 8 volts. Assume that the load

will draw 5amps. The power dissipation in the transistor will be Vce * Ic

or (8-5)*5=15watt.

The

software used for circuit design is EAGLE. The program consists of three main

modules: Layout Editor, Schematic Editor, Auto router which is embedded in a

single user interface. Therefore there is no need for converting net lists

between schematics and layouts. Its General

features are:

ุ online Forward- and Back-Annotation

ุ context sensitive help function

ุ no hardware copy protection

ุ multiple windows for board, schematic and library

ุ powerful User Language

ุ integrated text editor

ุ available for Windows und Linux

Layout Editor has following features

ุ maximum drawing area 1.6 x 1.6m (64 x 64 inch)

ุ resolution 1/10,000mm (0.1 micron)

ุ up to 16 signal layers

ุ conventional and SMT parts

ุ comes with a full set of part libraries

ุ easily create your own parts with the fully integrated

library editor

ุ undo/redo function for ANY editing command, to any depth

ุ script files for batch command execution

ุ copper pouring

ุ cut and paste function for copying entire sections of a

drawing

ุ design rule check

Schematic Editor provides the

following features

ุ up

to 99 sheets in one schematic

ุ electrical

rule check

ุ gate-

and pin swap

ุ create

a board from a schematic with a single command

The PCB design

comprises of three sections:

It

is a double sided PCB with the upper side of PCB comprising of the anode lines

of the LEDs .the cathode lines are laid on the bottom side of the PCB. The

anode lines are horizontal lines. The cathode lines are vertical lines.![cleardot[1]](final report_files/image032.gif) The track width is 10 mils. ((for 1A

current). circular pads has been laid with diameter of pad 0.5 mm greater than

hole diameter. Pads are laid for nodes

on the top side and holes for cathodes and vice versa.

The track width is 10 mils. ((for 1A

current). circular pads has been laid with diameter of pad 0.5 mm greater than

hole diameter. Pads are laid for nodes

on the top side and holes for cathodes and vice versa.

Tracks have angles

of 45 degree or so (never 90 degree).

PCB for led array

This

is designed as two layers PCB. The tracks never end at 90 degrees the VCC

tracks (20 mils) are having greater width than normal tracks. The ground tracks

are of width 40mils

This

is designed as two layers PCB. The tracks never end at 90 degrees the VCC

tracks (20 mils) are having greater width than normal tracks. The ground tracks

are of width 40mils

Led driver PCB

This is single sided PCB with provisions

for reset and program buttons and USB connector. The foot prints of PIC, resistors,

capacitors were provide by the software

Figure 18 Microcontroller PCB

|

|

|

|

|

|

|

|

|

SEND THE INCOMING

DATA TO 7219 VIA SPI.

|

|

The software used to send data is written in Visual C++ 6.0

#include <stdio.h>

#include "windows.h"

#include "mpusbapi.h" // MPUSBAPI Header File

//---------------------------------------------------------------------------

// Global Vars

char vid_pid[]= "vid_04d8&pid_000c"; // Default Demo Application Firmware

char out_pipe[]= "\\MCHP_EP1";

char in_pipe[]= "\\MCHP_EP1";

DWORD temp;

HINSTANCE libHandle;

HANDLE myOutPipe;

HANDLE myInPipe;

//---------------------------------------------------------------------------

// Prototypes

void GetSummary(void);

void LoadDLL(void);

void GetUSBDemoFWVersion(void);

DWORD SendReceivePacket(BYTE *SendData, DWORD SendLength, BYTE

*ReceiveData,

DWORD

*ReceiveLength, UINT SendDelay, UINT ReceiveDelay);

void CheckInvalidHandle(void);

//Custom Functions

void Raw7219(BYTE addr,BYTE data);

void LoadHigh();

int SendString(BYTE *send_buf,BYTE len);

void MakeRGBMap(BYTE *map, char *string);

#include "io_cfg.h"

#include "usb.h"

int main(int argc, char* argv[])

{

if(argc <= 2)

{

printf("\r\n-

USAGE : mdb.exe <id><len><string>");

return 1;

}

BOOLEAN bQuit;

DWORD selection=7;

bQuit = false;

// Load DLL when it is

necessary, i.e. on start-up!

LoadDLL();

LoadMap();

setRGB[0][0]=&setR1Col;

setRGB[0][1]=&setR2Col;

setRGB[0][2]=&setR3Col;

setRGB[0][3]=&setR4Col;

setRGB[1][0]=&setG1Col;

setRGB[1][1]=&setG2Col;

setRGB[1][2]=&setG3Col;

setRGB[1][3]=&setG4Col;

setRGB[2][0]=&setB1Col;

setRGB[2][1]=&setB2Col;

setRGB[2][2]=&setB3Col;

setRGB[2][3]=&setB4Col;

// Always a good idea to

initialize the handles

myOutPipe = myInPipe =

INVALID_HANDLE_VALUE;

int i,j;

BYTE color,rg_b,b_b;

char string[23];

printf("Enter the

string to be displayed : ");

gets(string);

printf("Enter the

color : \n");

printf(" 1. Red

\n");

printf(" 2. Green

\n");

printf(" 4. Blue

\n");

printf(" : > ");

scanf("%d",

&color);

printf("Displaying %s

with colour %d ",string,color);

printf("RG,B

Brightness [0-15] : ");

scanf("%d%d",&rg_b,&b_b);

//g_b=b_b=15;

//strcpy(string,"11");

//string[1]=255;

//string[1]='+';

//string[1]=0;

BYTE send_buf[64];

const int num_boards = 8;

int offset=0;

//color=7;

while(1)

{

//for(string[0]='A';string[0]<='Z';string[0]++,color++)

{

i=0;

color%=8;

if(!color)color=1;

//ClearBuffer(send_buf,64);

ClearAll7219();

BYTE

ic1=0,ic2=num_boards>>1;

int k=0,p=offset;

while(string[i])

{

while(map[string[i]][k?k-1:0])

{

if(ic2 ==

32)goto EOI;

if(p

>= 0)

{

(*setRGB[0][(p)%4])(ic1,ic2,(color

& 1)?map[string[i]][k]:0);

(*setRGB[1][(p)%4])(ic1,ic2,(color

& 2)?map[string[i]][k]:0);

(*setRGB[2][(p)%4])(ic1,ic2,(color

& 4)?map[string[i]][k]:0);

if(p

&& p%4==0)

{

ic1++;

ic2++;

}

}

k++;

p++;

}

i++;

k=0;

}

EOI:

{

InitMax7219(num_boards,send_buf,rg_b,b_b);

for(j=0;j<4;j++)

{

Shift7219(offset-1);

for(int

n=0;n<num_boards;n++)

{

if(num_boards-n-1

== 4)

max[num_boards-n-1].exportByteInverse(j,send_buf+2+4*n);

else

if((num_boards-n-1 == 5) || (num_boards-n-1 == 6))

max[num_boards-n-1].exportByteHalfInverse(j,send_buf+2+4*n);

else

max[num_boards-n-1].exportByte(j,send_buf+2+4*n);

}

SendString(send_buf,num_boards*4);

}

Sleep(300);

//offset--;

}

//for(i=2;i<2+32;i++)

// printf("%02x ",send_buf[i]);

//printf("\n");

} }

// Always check to close

all handles before exiting!

if (myOutPipe !=

INVALID_HANDLE_VALUE) MPUSBClose(myOutPipe);

if (myInPipe !=

INVALID_HANDLE_VALUE) MPUSBClose(myInPipe);

myOutPipe = myInPipe =

INVALID_HANDLE_VALUE;

// Always check to close the

library too.

if (libHandle != NULL)

FreeLibrary(libHandle);

return 0;

}//end main

The custom firmware code for translating the data from the Universal Serial Bus

(USB) to SPI for MAX7219

#include <p18cxxx.h>

#include <usart.h>

#include <delays.h>

#include "system\typedefs.h"

#include "system\usb\usb.h"

#include "io_cfg.h"

// I/O pin mapping

#include "user\user.h"

#include <spi.h>

/** V A R I A B L E S

********************************************************/

#pragma udata

byte counter;

byte trf_state;

DATA_PACKET dataPacket;

/** P R I V A T E P R O T O T Y P

E S ***************************************/

void BlinkUSBStatus(void);

void ServiceRequests(void);

void InitMAX7219(void);

void SendRaw7219Packet(void);

void OutSerialData(void);

/** D E C L A R A T I O N S **************************************************/

#pragma code

void UserInit(void)

{

mInitAllLEDs();

InitMAX7219();

}//end UserInit

/******************************************************************************

* Function: void ProcessIO(void)

*

* PreCondition: None

*

* Input: None

*

* Output: None

*

* Side Effects: None

*

* Overview: This function is a place holder for

other user routines.

* It is a mixture of both USB

and non-USB tasks.

*

* Note: None

*****************************************************************************/

void ProcessIO(void)

{

BlinkUSBStatus();

// User Application USB tasks

if((usb_device_state <

CONFIGURED_STATE)||(UCONbits.SUSPND==1)) return;

ServiceRequests();

}//end ProcessIO

void ServiceRequests(void)

{

byte index;

if(USBGenRead((byte*)&dataPacket,sizeof(dataPacket)))

{

counter = 0;

switch(dataPacket.CMD)

{

case READ_VERSION:

//dataPacket._byte[1] is len

dataPacket._byte[2] = MINOR_VERSION;

dataPacket._byte[3] = MAJOR_VERSION;

counter=0x04;

break;

case

RAW_MAX_PACKET://RAW_MAX_PACKET

SendRaw7219Packet();

dataPacket._byte[2]

= ~dataPacket._byte[2];

dataPacket._byte[3]

= ~dataPacket._byte[3];

counter=0x06;

break;

case

OUT_SERIAL_DATA:

OutSerialData();

LOAD7219

= 1;

dataPacket._byte[1]=0x02;

dataPacket._byte[2]=dataPacket._byte[0];

counter=0x03;

break;

case

PULSE_LOAD:

LOAD7219

= 1;

break;

case RESET:

Reset();

break;

default:

break;

}//end switch()

if(counter != 0)

{

if(!mUSBGenTxIsBusy())

USBGenWrite((byte*)&dataPacket,counter);

}//end if

}//end if

}//end ServiceRequests

/******************************************************************************

* Function: void InitMAX7219(void)

*

* PreCondition: None

*

* Input: None

*

* Output: None

*

* Side Effects: None

*

* Overview: Initializes the SPI port for MAX7219

*

*

* Note:

*

*

*****************************************************************************/

void InitMAX7219(void)

{

TRISCbits.TRISC7 = 0; //

Enabling SPI Pins Master mode

TRISBbits.TRISB1 = 0;

OpenSPI(SPI_FOSC_64,

MODE_00, SMPEND);

tris_LOAD7219 =

OUTPUT_PIN;

LOAD7219 = 0;

}//end InitMAX7219

void SendRaw7219Packet()

{

LOAD7219 = 0;

WriteSPI(dataPacket._byte[2]);

WriteSPI(dataPacket._byte[3]);

dataPacket._byte[4]=0x55;

dataPacket._byte[5]=0xAA;

LOAD7219 = 1;

counter = 0xff;

while(counter--);

}

void OutSerialData()

{

byte index;

//dataPacket.data[DATA_SIZE-1]

= 0; // Precaution null terminator

LOAD7219 = 0;

index = 0;

counter = dataPacket.len;

while(index<counter)

{

WriteSPI(dataPacket.data[index]);

index++;

}

}

/******************************************************************************

* Function: void BlinkUSBStatus(void)

*

* PreCondition: None

*

* Input: None

*

* Output: None

*

* Side Effects: None

*

* Overview: BlinkUSBStatus turns on and off LEDs

corresponding to

* the USB device state.

*

* Note: mLED macros can be found in

io_cfg.h

* usb_device_state is declared

in usbmmap.c and is modified

* in usbdrv.c, usbctrltrf.c,

and usb9.c

*****************************************************************************/

void BlinkUSBStatus(void)

{

static word led_count=0;

if(led_count == 0)led_count =

10000U;

led_count--;

#define mLED_Both_Off() {mLED_1_Off();mLED_2_Off();}

#define mLED_Both_On() {mLED_1_On();mLED_2_On();}

#define mLED_Only_1_On() {mLED_1_On();mLED_2_Off();}

#define mLED_Only_2_On() {mLED_1_Off();mLED_2_On();}

if(UCONbits.SUSPND == 1)

{

if(led_count==0)

{

mLED_1_Toggle();

mLED_2 = mLED_1; // Both blink at the same time

}//end if

}

else

{

if(usb_device_state ==

DETACHED_STATE)

{

mLED_Both_Off();

}

else if(usb_device_state

== ATTACHED_STATE)

{

mLED_Both_On();

}

else if(usb_device_state

== POWERED_STATE)

{

mLED_Only_1_On();

}

else if(usb_device_state

== DEFAULT_STATE)

{

mLED_Only_2_On();

}

else if(usb_device_state

== ADDRESS_STATE)

{

if(led_count == 0)

{

mLED_1_Toggle();

mLED_2_Off();

}//end if

}

else if(usb_device_state

== CONFIGURED_STATE)

{

if(led_count==0)

{

mLED_1_Toggle();

mLED_2 =

!mLED_1; // Alternate blink

}//end if

}//end if(...)

}//end if(UCONbits.SUSPND...)

}//end BlinkUSBStatus

ุ

Program

to drive the LED driver MAX 7219 has been obtained.

ุ

LED

matrix has been implemented

ุ

The

program for USB Interface has been run successfully

ุ

The USB

Interface has been implemented

ุ

The LED

Matrix could be developed for video display. Each LED represents a pixel. By

the intense packing of LEDs video display is possible.

ุ

The wireless LED board could be developed. GSM

and GPRS based Designs are Public utility products for mass communication. This

is a Scrolling (Moving) Message Electronic Display Board which displays the

messages received as SMS or GPRS Packets.

Datasheets referred :

ฐ

MAX7219

ฐ

PIC18F4550

ฐ

PIC16F84A

ฐ

TLC5940A

ฐ

RGB LED

Websites

referred:

www.microchip.com

www.ti.com

www.maxim-ic.com

All the

information present in this document and further information is available at

rgb.kitiyo.com

Appendix

Figure 19 Cost Report

|

ITEM

|

COST

PER UNIT(RS)

|

UNITS

|

TOTAL

(RS)

|

|

RGB

LED

|

10

|

128

|

1280

|

|

PIC

18F4550

|

FREE SAMPLE

|

|

|

|

LED driver

MAX 7219

|

FREE SAMPLE

|

|

|

|

PCB

|

|

|

500

|

|

Misc

Components

|

|

|

220

|

|

TOTAL

|

|

|

2000

|

ฐ MAX7219

ฐ PIC 18F4550